- Home Page

- Company Profile

-

Our Products

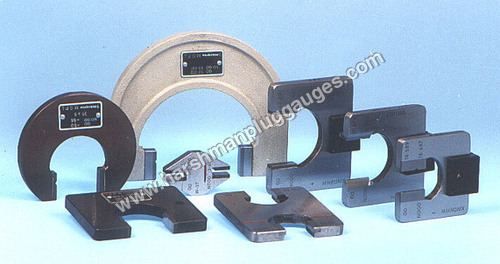

- Adjustable Snap Gauge

- Plug Gauges

- Automotive Thread Gauges

- Carbide Gauges

- Handles Collets

- Thread Wires

- Wire Units

- Measurement Gauge

- Measuring Pins

- Taper Guages

- Thread Calliper Gauge

- Correx Tension Gauges

- Spline Gauges

- High Precision Taps And Dies

- Ring Gauges

- Air Gauges

- Thread Gauges

- Plain Gauges

- Customize Gauges

- Contact Us

Showroom

Designed for rapid dimensional inspection, adjustable snap gauges are widely used for checking external diameters with accuracy. Supplied in robust constructions, these gauges allow fine adjustments, ensure repeatable results, and support efficient quality control in machining, automotive, and precision engineering environments.

Manufactured for internal diameter inspection, plug gauges are essential tools in precision measurement. Offered in various sizes and tolerances, they ensure accurate hole verification, consistency in production, and compliance with engineering standards across tool rooms and manufacturing units.

Engineered to meet automotive quality requirements, automotive thread gauges are used to inspect threaded components with precision. Available in multiple thread standards, they help maintain dimensional accuracy, reduce assembly errors, and support reliable quality assurance in automotive manufacturing processes.

Known for exceptional hardness and wear resistance, carbide gauges are suitable for high-usage inspection environments. These gauges maintain accuracy over extended periods, resist deformation, and support consistent measurement results in demanding industrial and precision machining applications.

Designed for secure mounting and ease of handling, handles collets support efficient use of gauges and measuring tools. Supplied in durable materials, they ensure firm grip, stability, and operator comfort during repetitive inspection and measurement tasks.

Developed for accurate measurement of effective thread diameter, thread wires are supplied in matched sets for precision inspection. They offer reliable contact points, high dimensional stability, and are widely used in calibration and quality control of threaded components.

Configured for precise thread measurement applications, wire units provide consistent and repeatable inspection results. These units support accurate pitch diameter evaluation and are suitable for use in tool rooms, calibration labs, and manufacturing quality control departments.

Used for verifying dimensions and tolerances, measurement gauges support efficient inspection across manufacturing processes. Available in varied designs and ranges, they help maintain production accuracy, reduce rework, and ensure conformity to specified engineering standards.

Precision ground for dimensional accuracy, measuring pins are used for checking hole sizes, slot widths, and spacing. Supplied in sets or individual sizes, they provide reliable measurements and are essential tools for inspection, calibration, and quality verification tasks.

Designed to check taper angles and dimensions, taper gauges assist in accurate inspection of conical components. These gauges help ensure proper fitment, alignment, and functional accuracy in machining, tooling, and mechanical assembly applications.

Built for quick and accurate thread measurement, thread calliper gauges allow easy verification of thread pitch and diameter. Their practical design supports fast inspection, reduces handling time, and improves productivity in workshop and quality control environments.

Engineered for measuring belt and material tension, correx tension gauges provide accurate and repeatable readings. These gauges support preventive maintenance, proper installation, and performance optimization in mechanical systems and industrial equipment.

Used for inspecting spline profiles and dimensions, spline gauges ensure accurate fit and alignment in mechanical assemblies. Supplied in various standards, they support precision inspection requirements in automotive, aerospace, and heavy engineering industries.

Manufactured for accurate thread cutting and repair, high precision taps and dies ensure clean, consistent threads. Supplied in multiple sizes and standards, they support machining accuracy and reliable performance in production and maintenance applications.

Designed for external diameter and thread inspection, ring gauges provide fast go and no go verification. These gauges ensure dimensional accuracy, repeatability, and compliance with tolerance requirements in precision manufacturing and quality assurance processes.

Utilizing pneumatic measurement principles, air gauges deliver high-precision, non-contact inspection of internal dimensions. They offer fast response, minimal wear, and consistent accuracy, making them suitable for high-volume production and advanced quality control environments.

Developed for verifying thread accuracy, thread gauges support reliable inspection of pitch, angle, and diameter. Available in multiple thread forms and standards, they help maintain product quality and reduce assembly issues in threaded components.

Used for checking simple dimensional features, plain gauges provide quick and reliable inspection of sizes and limits. These gauges are essential for ensuring consistency, reducing measurement errors, and supporting efficient quality control in manufacturing operations.

Tailored to specific inspection requirements, customize gauges are supplied to match unique dimensions and tolerances. These gauges support specialized applications, improve measurement efficiency, and ensure accurate quality control for non-standard or application-specific components.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese